Industry 4.0 is transforming manufacturing, but training content hasn’t kept up. It’s often scattered, outdated, and disconnected. This blog explores how a centralized, AI-ready learning ecosystem helps manufacturers keep teams aligned, compliant, and ready for what’s next—and how MadCap Syndicate makes it possible.

Smart factories aren’t a future vision. They’re already here. Manufacturers today are entering the era of Industry 4.0 (the Fourth Industrial Revolution), where digital technologies are integrated across the entire production lifecycle. This includes everything from automation and machine learning to real-time data and connected systems that drive faster, more adaptive operations.

But while production systems have advanced rapidly, training environments haven’t kept up. Content is often fragmented and updated manually. Critical knowledge is still buried in static documents that are difficult to access and nearly impossible to scale. That disconnect puts workforce readiness and operational consistency at risk.

Keeping up with Industry 4.0 requires more than just modern machines. It takes a training system that can evolve alongside your operations, scale across regions, adapt to specific roles, and support intelligent technologies like AI. And for AI to work as intended, it must be fueled by clean, structured content that’s easy to manage and deliver at scale.

That’s where a dynamic learning ecosystem comes in.

What Is a Dynamic Learning Ecosystem?

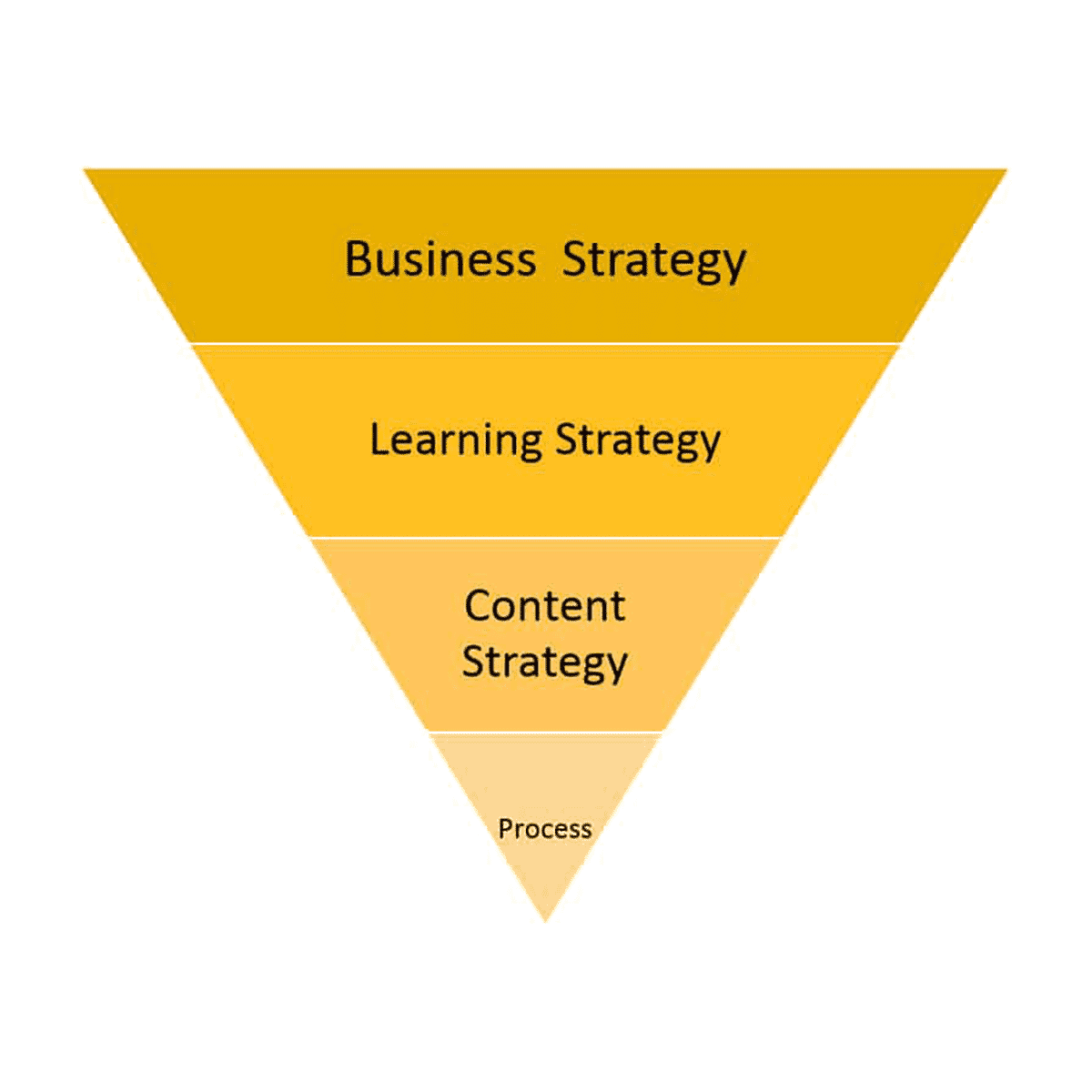

A dynamic learning ecosystem is a modular framework designed to adapt alongside your business. It brings together four foundational layers:

- Centralized content management

- Metadata-driven organization

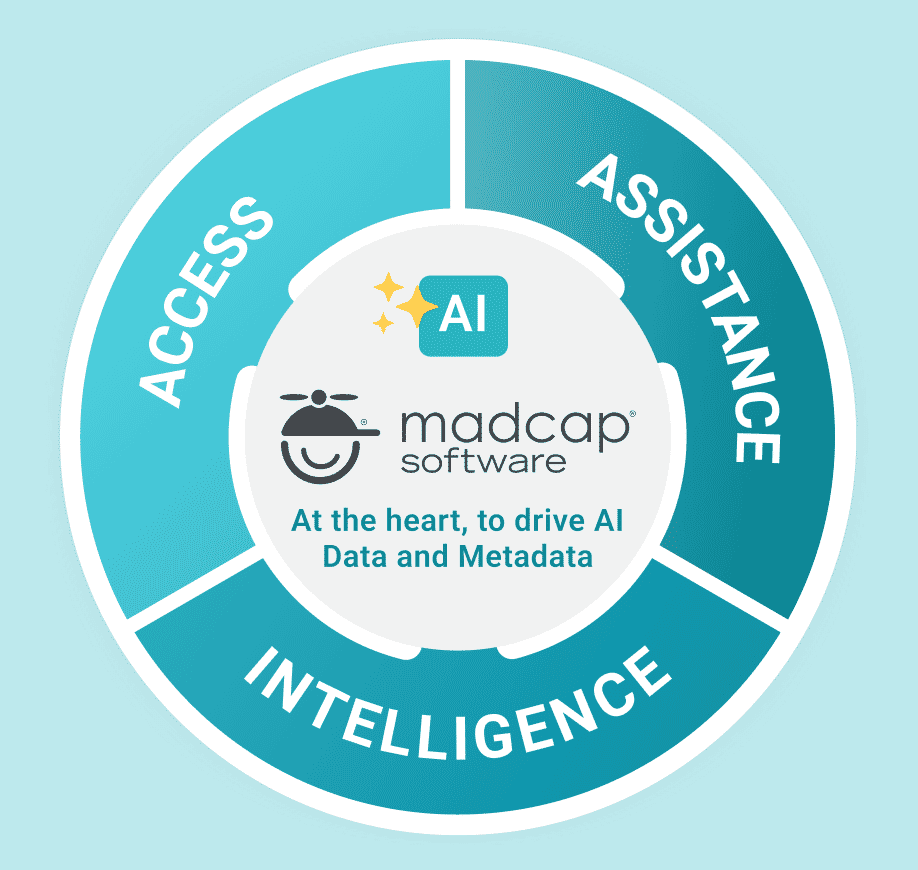

- AI integration that works with your proprietary content

- Personalized learner experiences that align with production needs

Together, these capabilities support a learning system that is flexible, scalable, and built to evolve with your operations.

1. Centralized content that works across teams and regions

Manufacturing organizations manage a wide range of training content. From multilingual safety protocols to machine-specific standard operating procedures (SOPs), keeping content accurate and consistent across teams is a constant challenge.

When that content lives in disconnected systems or in files that must be updated manually, such as Word documents or PowerPoint decks saved on individual desktops, it becomes difficult to maintain version control or ensure compliance. This increases the risk of outdated procedures being followed on the floor, safety incidents due to missing updates, and audit failures when documentation can’t be verified. The result is slower workflows, duplicated effort, and greater exposure to operational and regulatory issues.

MadCap Syndicate provides a centralized foundation for managing and distributing content. Updates can be made once and deployed everywhere, reducing redundancy and administrative overhead. Whether you are rolling out a new machine or revising a policy, content remains aligned across every facility.

For example, if a regional safety procedure is updated, that change automatically flows into every relevant course or checklist, ensuring that operators and managers are always working with the latest version.

2. AI that connects to your internal knowledge

Off-the-shelf AI tools often miss the mark in manufacturing settings. That’s because they are not connected to the proprietary content that drives your operations. Procedures, compliance documents, and equipment manuals are unique to your business.

MadCap Syndicate supports Retrieval-Augmented Generation, or RAG. This approach allows AI to pull from your internal documents in real time, providing accurate and contextual support to employees.

Picture a technician running into an issue during a shift. Instead of flipping through binders or waiting on a supervisor, they can ask an AI-powered assistant for step-by-step guidance, drawn from the most current SOPs. The result is faster resolution, fewer errors, and more confident decisions on the floor.

3. Metadata that delivers precision and compliance

Structured metadata is what turns learning content into a flexible, responsive asset. By tagging content by role, machine type, facility location, and learning objective, organizations can serve the right training to the right person at the right time.

Let’s say a technician is transitioning to a new CNC machine. Smart metadata ensures they automatically receive training materials specific to that model, including safety procedures and maintenance checklists. Meanwhile, a supervisor who completes a leadership module might be served follow-up content on inventory management or analytics.

Metadata also makes it easier to track completion, demonstrate audit readiness, and identify learning gaps. If regulators request training logs, metadata lets you quickly confirm which teams completed which training, on what version of the content, and when.

4. Learner experiences that match the rhythm of production

Training should meet workers where they are: on the floor, between shifts, or preparing for new roles. With a dynamic learning ecosystem, manufacturers can deliver experiences that are adaptive, timely, and aligned with real-world production needs.

Before a scheduled line change, operators might receive targeted refresher modules to reinforce key steps. Assessments can adapt in real time, offering extra support when needed and skipping over material the learner has already mastered. And instead of pausing work to look something up, employees can ask a chatbot and get instant answers to safety or process questions right when they need them.

MadCap Syndicate supports these learning pathways across platforms like Learning Management Systems (LMSs), mobile apps, and custom portals. And because content is centrally managed, it stays consistent no matter where it’s delivered.

Why This Matters Now

According to the World Economic Forum, nearly 60 percent of the global workforce will need reskilling by 2030. For manufacturers, that transformation is already underway. As Industry 4.0 introduces smarter machines, tighter regulations, and more data-driven workflows, training systems must evolve in parallel.

AI and automation may be the future, but training is the bridge that gets you there. Without an ecosystem designed for scale and adaptability, the gaps between operations and workforce readiness will only grow wider.

A dynamic learning ecosystem closes that gap. It helps manufacturers keep knowledge flowing, systems aligned, and employees equipped for whatever comes next.

Make Training a Competitive Advantage

The manufacturers seeing the most success with AI are the ones who started by fixing their content. They built structured systems that could evolve, adapt, and support real-time learning. MadCap Syndicate gives you the tools to do the same—so your training isn’t just up to date, it’s built to power what’s next.

Get the white paper to learn how to make your content AI-ready and unlock a dynamic learning ecosystem that drives consistency, agility, and results across your organization.